Understanding Poly Bags: A Comprehensive Guide

- 1. What Are The Different Types of Poly Bags?

- 2. How Are Poly Bags Manufactured?

- 3. What Are The Common Applications of Poly Bags?

- 4. What Are The Benefits of Using Poly Bags?

- 5. What Poly Bag Regulations and Best Practices Should I Be Aware Of?

- Frequently Asked Questions

- What does ‘wicketed’ mean when referring to poly bags?

- Does the Closure Type Make a Difference in How Protective My Poly Bag Is?

- Can I Recycle My Used Poly Bags?

- Conclusion

- Posts navigation

Share this Article

Poly bags are one of the most common packaging solutions used by businesses today. These bags are made of polyethylene or similar plastic compounds, which makes them lightweight, durable, and versatile. From shipping and mailing to healthcare and advertising, poly bags are used in many industries worldwide. However, not all poly bags are created equal, and selecting the right one for your business needs can be overwhelming. In this comprehensive guide, we’ll explore everything you need to know about poly bags, including their types, construction, and applications.

1. What Are The Different Types of Poly Bags?

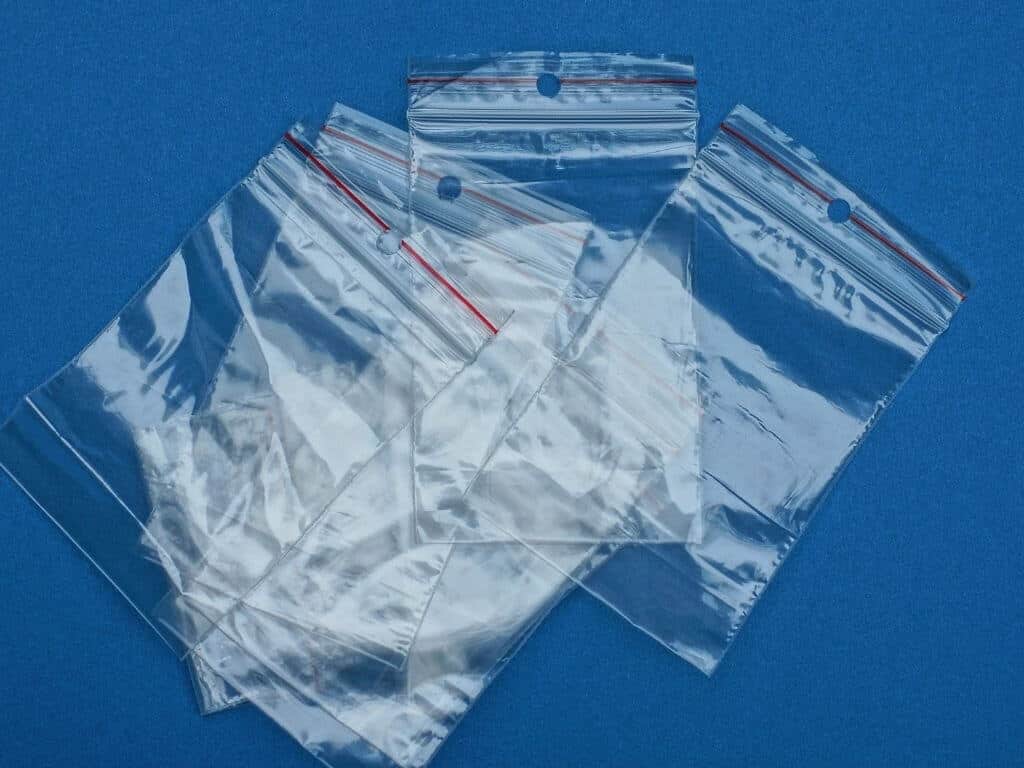

Poly bags come in various types that have unique features and applications. There are different types such as wicketed bags, pre-opened bags, reclosable packaging bags, and trade show bags that are used for specific purposes. Wicketed bags are perfect for high-speed packaging lines, while pre-opened bags on a roll are suitable for manual packaging operations. Reclosable packaging bags come with a zipper, making them ideal for storing items that need to be opened and closed frequently. Trade show bags are customized to meet the needs of exhibitors and make it easy to transport their products.

2. How Are Poly Bags Manufactured?

Poly bags are made by extruding and molding polyethylene or similar plastic compounds into the desired shape and size. They can be made from virgin or recycled materials, with the latter being the more sustainable option. Poly bags can also be plain or printed, with custom printing options available to businesses who want to add their branding, communication, or product information to the packaging.

3. What Are The Common Applications of Poly Bags?

Poly bags have numerous applications across various industries. In the retail industry, they’re used to pack and label products, such as clothing, accessories, and electronics. In the medical and healthcare industry, they’re used for sterile equipment storage, medication packaging, and biohazard waste disposal. In the shipping and mailing industry, they’re used to protect items during transit and storage. In the advertising industry, they’re used as promotional bags, gift bags, and event swag.

4. What Are The Benefits of Using Poly Bags?

Poly bags offer numerous benefits that make them ideal for businesses of all sizes. First, they’re lightweight, making them easy to handle and cheaper to ship. Second, they’re durable and provide excellent protection against dust, moisture, and other environmental factors. Third, they’re affordable, making them ideal for small businesses, startups, and budget-conscious businesses. Fourth, they’re customizable, allowing businesses to add their branding or messaging to the packaging. Finally, they’re eco-friendly, with recycled poly bags being a sustainable option for businesses looking to reduce their environmental footprint.

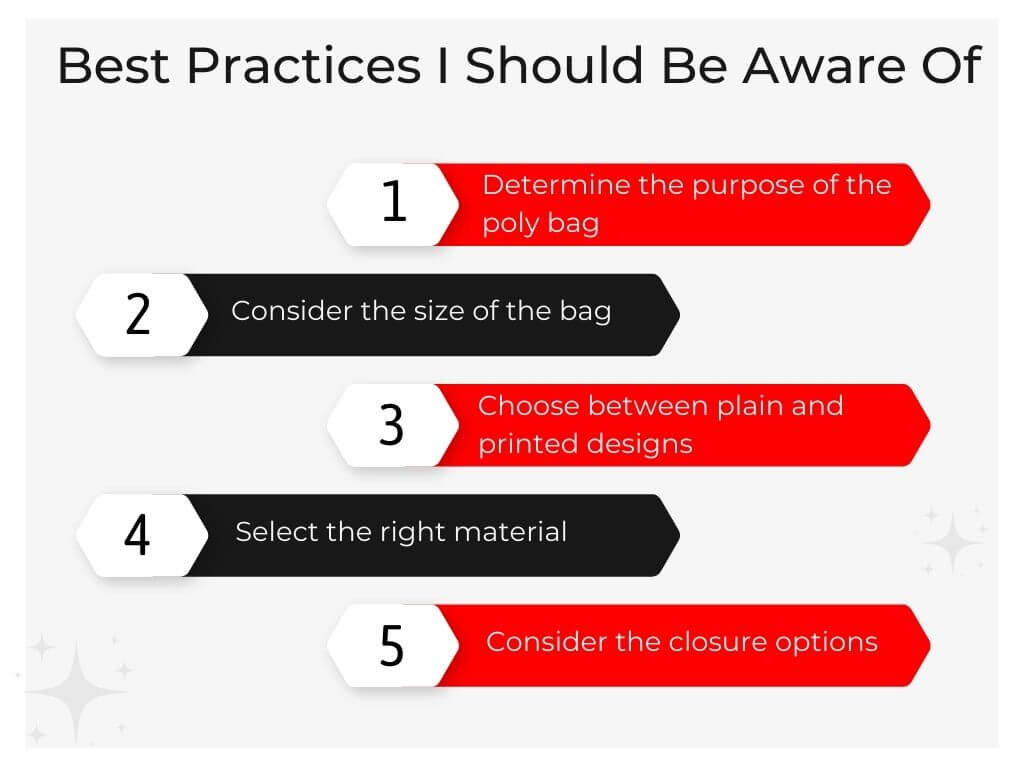

5. What Poly Bag Regulations and Best Practices Should I Be Aware Of?

The medical and retail industries have very specific regulations when it comes to using poly bags. In the medical industry, poly bags are primarily used for sterile equipment storage, medication packaging, and biohazard waste disposal. The FDA has strict guidelines regarding these applications, which dictate the type of materials that should be used and how they should be stored. For retail applications, poly bags must comply with national and international packaging regulations. These guidelines cover topics such as labeling, plastic composition, and thickness of the bag. Additionally, businesses must adhere to best practices when using poly bags, such as selecting the right type of bag, using appropriate sizing to avoid waste, and disposing of used bags responsibly. Here are 5 of the best practices you can follow:

1. Determine the purpose of the poly bag

Before selecting a poly bag, consider its intended use and the environment it will be in. For example, stretch wrap bags are great for protecting products during shipping, while reclosable packaging bags are ideal for storing items that may need to be opened or closed frequently.

2. Consider the size of the bag

The bag’s size should be appropriate for the items or products you need to store, package, or ship. If your items require a lot of space in the bag, then opt for larger-sized bags instead of cramming them into smaller ones.

3. Choose between plain and printed designs

Depending on your budget and needs, you can opt for either plain or printed poly bags. If you need to add branding or messaging to your packaging, then consider custom printing options.

4. Select the right material

Polyethylene is the most common material used in making poly bags, but there are other materials that may be better suited for certain applications. For example, LDPE and LLDPE materials are best for packaging products with sharp edges or corners.

5. Consider the closure options

Poly bags come with various closure options, such as zip closures, side-seal gusseted bags, and wicketed bags. Make sure you select the right type of closure to ensure your products are sealed securely.

By following these tips, you can be sure to select the right poly bags for your project or business needs. With their lightweight construction, durability, and affordability, poly bags are a great packaging solution for businesses of all sizes. Whether you’re shipping products or storing items in sterile environments, there’s a poly bag for every application. With this comprehensive guide, you now have a better understanding of poly bags and can make an informed decision when selecting them for your business needs.

Frequently Asked Questions

What is the difference between LDPE, HDPE, and LLDPE Poly Bags?

LDPE, HDPE, and LLDPE are all types of polyethylene plastics, which are commonly used to create poly bags. Each plastic material has unique properties that make it suitable for different applications.

Low-density polyethylene (LDPE) is a lightweight yet strong plastic that is highly flexible and offers excellent resistance to punctures and tears. It is often used to create food-grade bags, frozen food packaging, and wood panel wrapping.

High-density polyethylene (HDPE) is less flexible than LDPE but provides superior strength and durability. It is most commonly used for heavy-duty applications such as shipping sacks, laundry bags, and heavy-duty garbage bags.

Linear low-density polyethylene (LLDPE) is a type of plastic that provides excellent flexibility, strength, and durability. It is commonly used for shipping products with sharp edges and corners, such as furniture, electronics, and pharmaceuticals.

What does ‘wicketed’ mean when referring to poly bags?

Wicketed poly bags are an efficient and economical packaging solution for businesses of all sizes. They use multiple interlocking tabs, which look like a wicket, to hold the bag in place on a rack or spindle. This allows for higher-speed packaging lines and simpler manual packaging operations.

Wicketed bags are made from lightweight and durable materials and are perfect for applications such as food packaging, apparel, medical supplies, and other retail items. They provide a secure closure to keep products inside the bag, but can easily be opened by the customer or store employee.

Does the Closure Type Make a Difference in How Protective My Poly Bag Is?

The type of closure on a poly bag can have a significant impact on how protective it is and the degree of protection it offers. For instance, zip closures provide an air- and water-tight seal that helps keep items away from moisture, dust, and other contaminants. On the other hand, side-seal gusseted bags are not as secure and can be opened easily, making them suitable for products that need to be frequently accessed. It’s important to choose the right closure type based on your product’s needs and the environment it will be stored in.

Can I Recycle My Used Poly Bags?

Yes, many types of poly bags are recyclable, but it’s important to check with your local recycling center first. If you’re looking for a more sustainable packaging solution, you can also opt for recycled poly bags that are made from 100% post-consumer waste. These bags are just as strong and durable as regular poly bags but have less of an environmental impact.

Conclusion

Poly bags are versatile, affordable, and customizable packaging solutions that can help businesses streamline their operations while protecting their products. By understanding the types, construction, and applications of poly bags, businesses can make informed decisions on which bags best suit their needs. At the same time, it’s essential to comply with regulations and best practices for using poly bags, particularly in industries prone to contamination or safety risks. Ultimately, using poly bags can enhance businesses’ efficiency, safety, and sustainability practices.

If you need help choosing the right type of poly bag or customizing them to meet your specific requirements, contact us today!